Changing from steel chains to Timing Belts with Pin Joint

A multinational OEM for tissue packaging packs tissues into foil. With the help of bars, two parallel belts push tissues into the machine. Up to this point, the OEM used steel chains that made noise because of the contact with the sprocket, and left dirty marks on the machine.

To solve this problem, the OEM required a precise, low noise, lubricant-free and fast replacement of the steel chains by TPU timing belts. Speed and hygiene are also very important due to low product price and consumer use of tissue products.

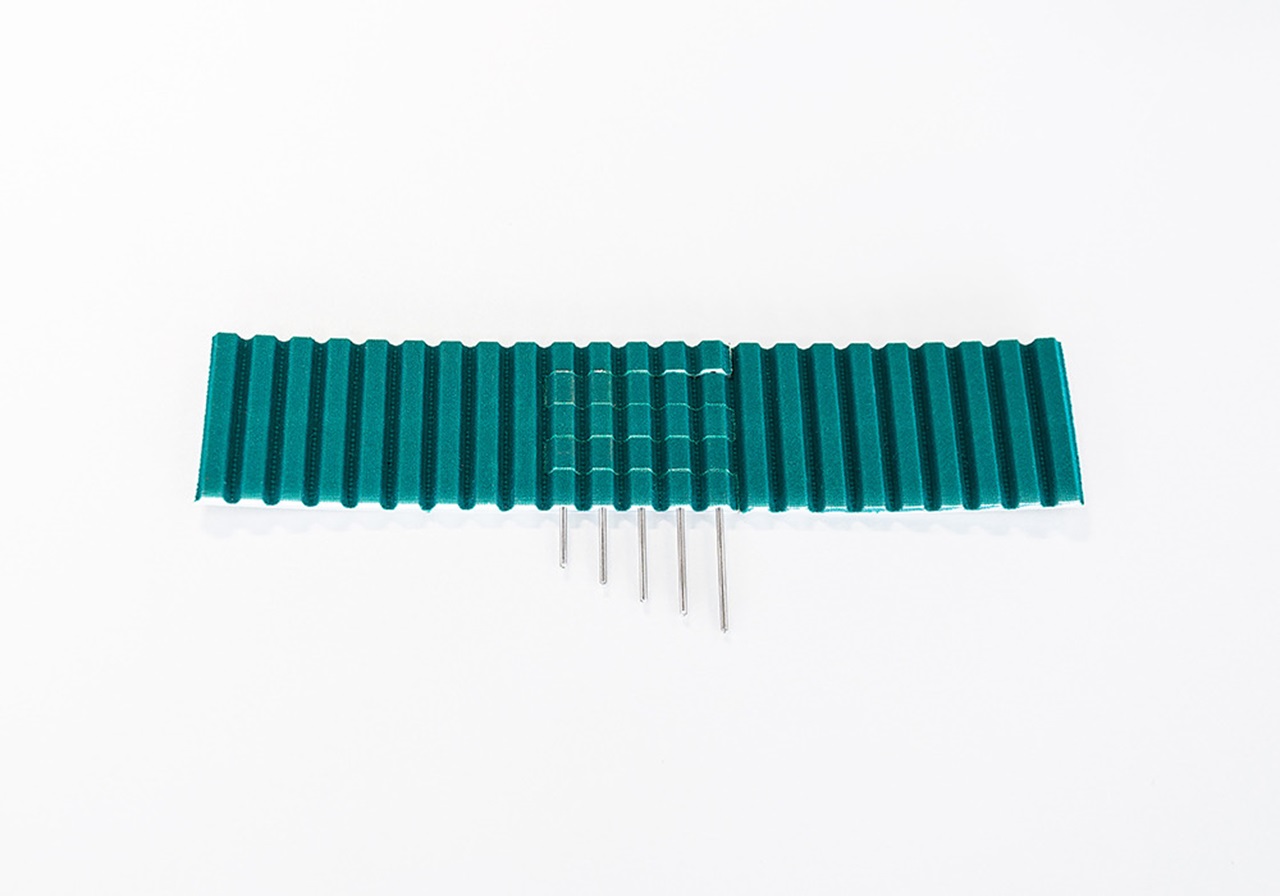

Habasit satisfied this requirement with the AT10-S-01UU6X25 Timing Belt with Pin Joint that is very quiet and clean, it allows high speeds and easy replacement for the customer. Once installed, the Timing Belts with Pin Joint are running on HabiPLAST without the need to lubricate chains near tissues as they did in the past.

Improvements included a cleaner environment and reduced noise, as well as improved levels. Finally, the flowpack machine has a much more modern look with timing belts, and the maximum speed is comparatively higher.