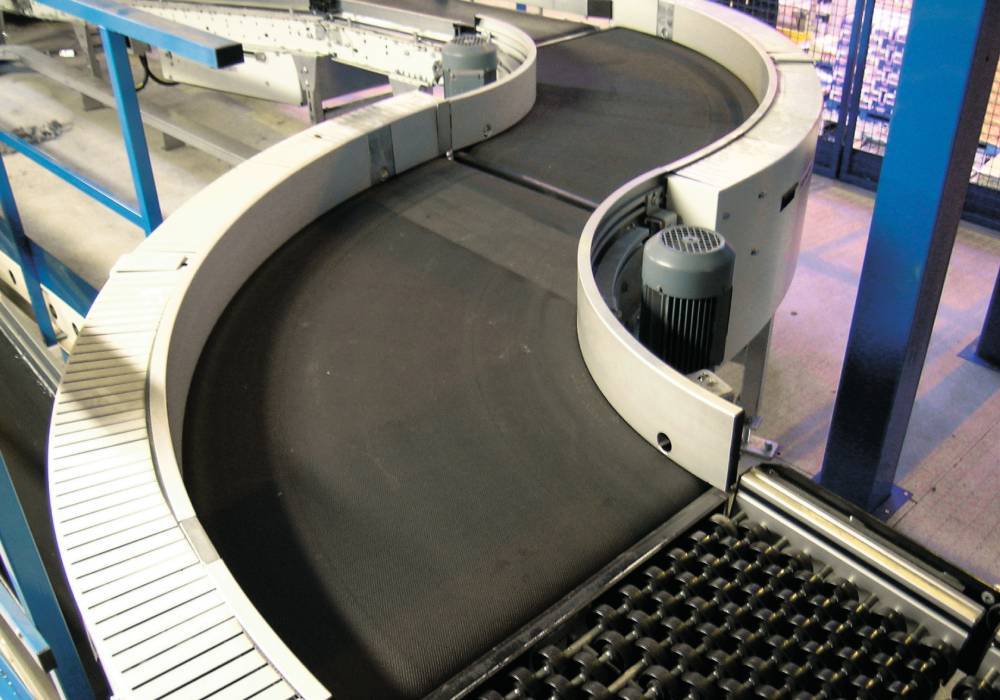

How to prevent unplanned production stops during e-commerce peak season

As one of the biggest shopping days in the calendar, Black Friday marks the start of a festive shopping frenzy. However, while manufacturers may enjoy a spike in sales, the strain of increased demand can amplify existing supply chain problems. Adriano Parmesani, Industry Segment Manager Distribution Centers, discusses the preventative measures plants can take to keep their conveyor belts running smoothly during the e-commerce peak season.