US customer saves $105,000 a year by switching to HabaSYNC T-5 timing belts for paper wipes manufacturing

Customer benefits from belts that last twice as long, with less downtime and higher productivity

Wet wipes are among the world’s most frequently used products. An average consumer in the US reached for them over 30 times per week in 2020, and sales of disinfecting wipes have grown 5 times since the COVID-19 pandemic. We use them for personal hygiene, baby care, household cleaning and in medical and industrial settings. Their production is a complex process that requires great precision and efficiency, from cutting individual wipes to folding and stacking prior to packaging. Process automation for the stacking application, depends on a compression belt to ensure consistency and efficiency.

A US-based paper hygiene-product manufacturer with a global presence was facing frequent belt replacements in this application, which led to raised costs and loss of productivity, also connected with long lead times for their replacement belts. The company turned to Habasit for assistance in finding a more reliable solution with better life performance for their compression belt.

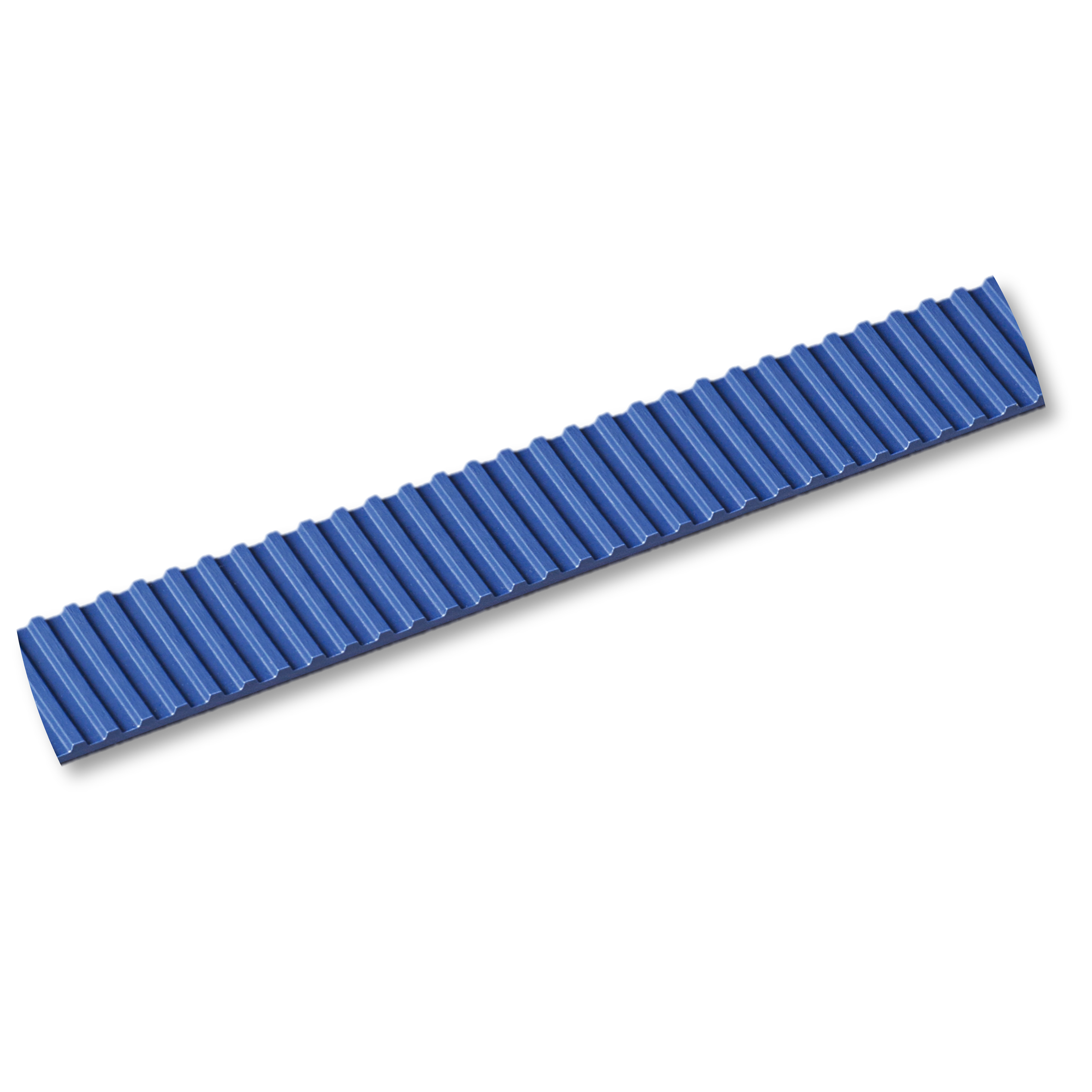

To meet the customer’s process requirements, we suggested our proven HabaSYNC open-end T-5 timing belt in blue food-grade TPU with aramide, and a nub pattern top cover. Once installed the belts fully matched the customer’s application needs, performing the compression job perfectly, with no marking on the wipes.

The immediate savings potential delivered by the short lead-time alone amounted to $69,900 a year. However, the customer soon discovered a major added benefit: Habasit belts last nearly twice as long as the predecessor belts. Given that longer belt lifetimes mean less downtime and fewer maintenance hours, the customer estimates annual savings of almost $105,000.

A US-based paper hygiene-product manufacturer with a global presence was facing frequent belt replacements in this application, which led to raised costs and loss of productivity, also connected with long lead times for their replacement belts. The company turned to Habasit for assistance in finding a more reliable solution with better life performance for their compression belt.

To meet the customer’s process requirements, we suggested our proven HabaSYNC open-end T-5 timing belt in blue food-grade TPU with aramide, and a nub pattern top cover. Once installed the belts fully matched the customer’s application needs, performing the compression job perfectly, with no marking on the wipes.

The immediate savings potential delivered by the short lead-time alone amounted to $69,900 a year. However, the customer soon discovered a major added benefit: Habasit belts last nearly twice as long as the predecessor belts. Given that longer belt lifetimes mean less downtime and fewer maintenance hours, the customer estimates annual savings of almost $105,000.