A-5’s Excellent Strength and Splice Overcome Monthly Belt Failures

A tissue products manufacturer experienced regular belt failures on a couch roller, which is a perforated metal cylinder used to dewater wet paper web through high-speed rotation. The competitor's belt used to power the couch roller lasted only about 30 days before belt failure. The high speeds and forces of the application resulted in delamination or splice failure and costly maintenance and production loss.

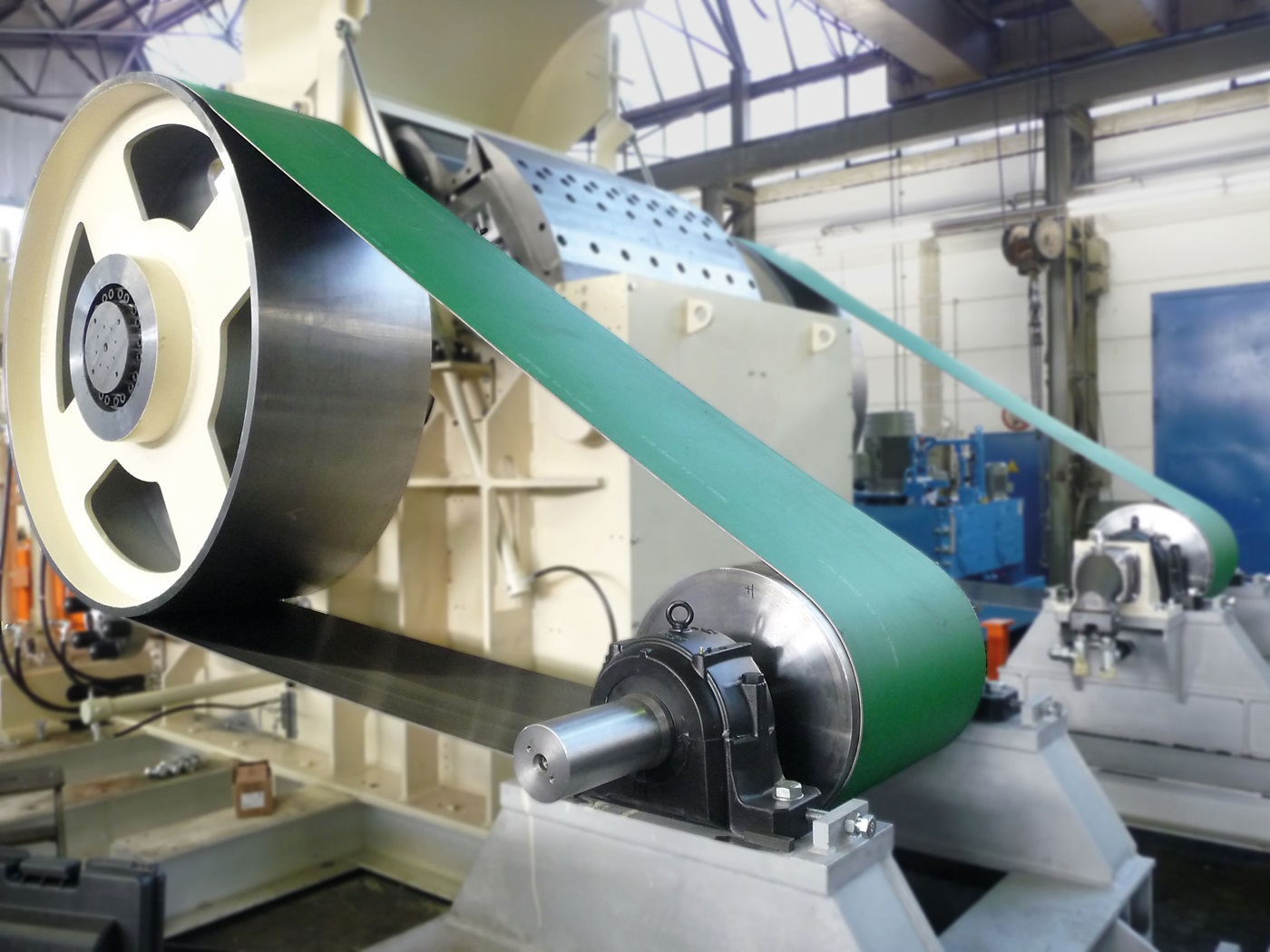

To solve the costly belt failures, the manufacturer required a stronger and more durable power transmission belt fabricated with a consistent and reliable splice. Habasit satisfied this requirement with the A-5, a robust power transmission belt sporting a tensile strength (1% elongation) of 30 N/mm and a durable chemical bond through Habasit's meticulous Thermofix joining process.

Once installed, the A-5 outperformed the competitor's belt by an outstanding margin—upgrading the measure of belt life from months, to years.

Overall, the exceptional belt life and performance delivered big benefits:

- 12-to-1 improvement in belt life

- Over $6,000 in saved production

- Over $20,000 in belt replacement savings

Total annual savings surpassed $28,000.