New belting solutions for your mixing line challenges

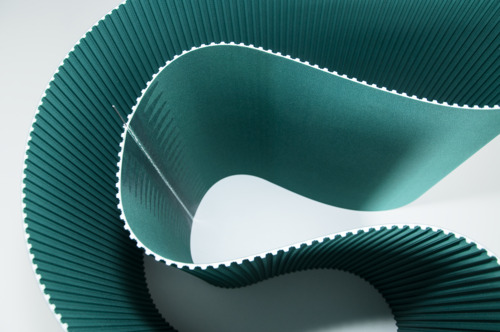

Double lifetime, no risk of contamination - silicon-coated belts

- 80% lower lifecycle cost; doubled belt lifetime

- No risk of rubber compound contamination

- Fewer rejects and less waste

- Operation stability even with unbalanced loading

- Fewer line stops and less maintenance downtime

Meeting your needs for belting with lower total costs of ownership, less maintenance, and higher productivity, our new single- and double-sided silicon-coated belts are proven to last twice as long as competitor belts.Giving you an 80% lower lifetime cost thanks to exceptional durability and high contact temperature- and delamination resistance, they handle even unbalanced and heavy loads with ease. Your tires and your reputation are safe, with far fewer rejects and less waste, as the rubber mix is never contaminated by silicon migration.

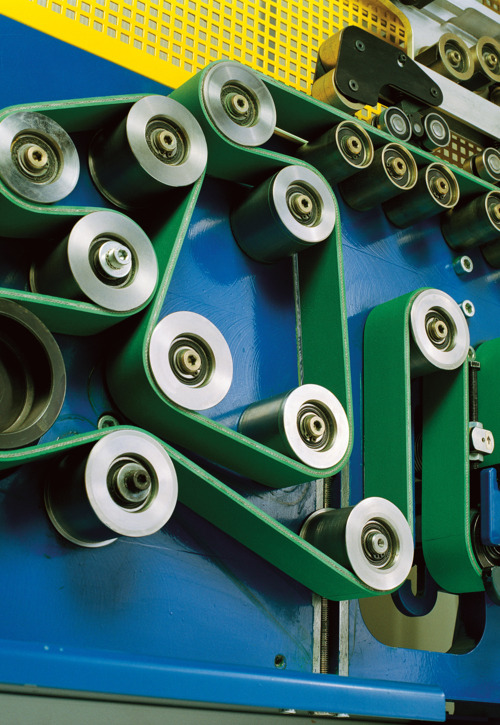

Unique, no vacuum adhesion - PBT Diamond Top Heavy Duty belt

- Smooth operation with no rubber vacuum adhesion

- Hassle-free belt maintenance

- Fast and easy belt replacement

- Longer, damage-free belt lifetime

Delivering a significantly longer belt lifetime, less downtime, and a lower lifetime cost, our unique new heavy-duty PBT-based belt demonstrates exceptional strength at contact temperatures above 120° C. The diamond top negative structure prevents vacuum adhesion between the rubber and the belt without affecting the rubber compound. Your requirements for excellent chemical resistance, easy belt maintenance, and fast, screwdriver assembly and disassembly are all met by this excellent new belting solution

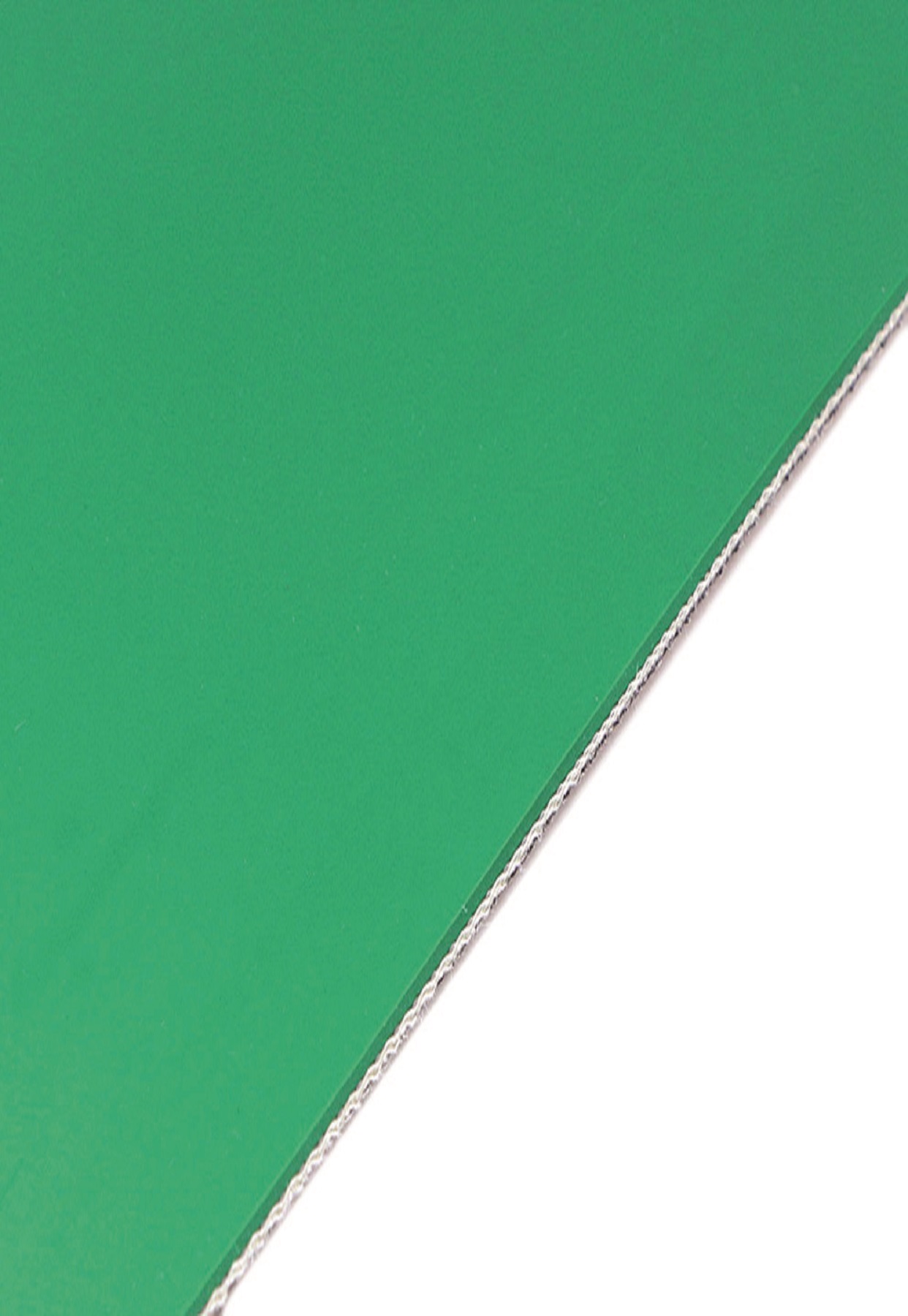

Ideal for uncured rubber release and cut-sensitive operations - robust, multi-purpose belt

- Reliable performance in contact with uncured rubber

- Safe to use in cut-sensitive operation

- Smooth transmission of heavy goods

When you demand nothing less than reliable performance in contact with uncured rubber, good release and cut-resistance properties, along with good belt tracking for secure and even transport, our new multi-purpose heavy-duty belt delivers it all. And if you’re seeking a streamlined supplier chain for even greater efficiency, the introduction of this new belt means you can have it: Habasit is the only belting supplier to offer every type of belt used in tire manufacturing

Featured products